Innovative liquid packaging solutions provide food processors and preservers with the ability to quickly and efficiently package their products. Depending on the packaging method, each solution has benefits that make it an ideal choice for any product. The features that a packaging machine offer also plays a vital role in optimizing the process and ensuring that a quality product is provided to the customer.

Let’s look at some methods and their benefits used in liquid packaging machines and solutions.

1. Methods Used in Packaging

The main focus of the methods of packaging is to avoid contamination. Some of the main methods used in a liquid packaging machine are:

- Aseptic liquid filling and sealing

Aseptic processes involve sterile, sealed containers that are pressure-filled with liquids and then hermetically sealed.

This packaging ensures that food products remain safe and free from contamination while in transit or on store shelves. Additionally, aseptic technology allows food to be stored and transported without refrigeration.

- Modified atmosphere packaging

Also known as MAP, in this process, gases such as nitrogen, oxygen, and carbon dioxide are used to reduce or prevent the spoilage of food products. This type of packaging also helps to extend the shelf-life of food products.

- Vacuum packaging

This method packages liquid items with minimal oxygen exposure. Vacuum packaging removes air from the container, creating an environment that helps keep the product fresh.

It prevents moisture and other contaminants from entering the container.

- Shrink-wrapping

This process involves placing a product in a heat-sealed bag or container and then shrinking the material around it. Shrink wrap helps to protect fragile items during transport and storage. Additionally, it is used to create tamper-proof packages that make it easier to store liquids.

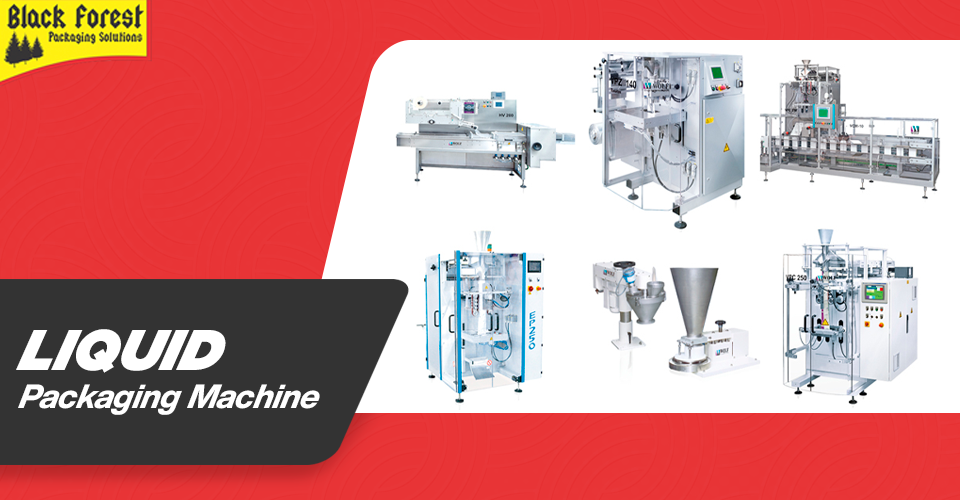

2. Features of an Innovative Liquid Packaging Machine

We are one of liquid packaging machine manufacturers in the market that make innovative machines.

Here are some features a liquid packaging machine should have to make it an ideal choice for any product.

- Automatic – avoid the cost of manual labor

- Stainless steel sanitary design – Durable and easy to clean

- High output speed – Fills and seals packages in seconds

- User-friendly controls – Easy to operate even by non-technical personnel.

- PLC control system – High-precision digital control with fault diagnosis, adjustment, and error detection.

- Quick changeover – Minimize downtime between product changes.

- Multiple filling systems – Single, dual, and multiple components fill.

- Sealing – clean, strong sealing with air removal

- Freezing capacity – extreme temperatures to freeze liquids

- Bags – Provides a precise range of bag sizes

3. Benefits of Using an Innovative Liquid Packaging Solution

- Safety and Quality- The methods and technology used for packaging will ensure your food products remain safe and free from contamination. Additionally, it helps to extend the shelf-life of food items by avoiding spoilage caused by oxygen and other contaminants.

- Cost Efficiency – These machines are designed to be cost-effective, allowing you to package large quantities of food quickly and efficiently. Using a liquid packaging machine will save time, money, and resources.

- Versatility – With features like quick changeover and multiple filling systems, you can easily package different types of liquids with one machine. This makes it easy to switch between products without purchasing multiple machines.

- Eco-Friendly – Innovative liquid packaging solutions are designed to be energy efficient, helping to reduce your carbon footprint. Additionally, these machines use less material and produce less waste, making them an environmentally friendly option.

Black Forest offers top-of-the-line machines designed to ensure accurate and repeatable performance for those looking for the highest quality liquid packaging solutions. Our Liquid Master line of machines is ideal for various liquid packaging applications and can produce containers in a wide range of sizes. Call us today!

Recent Comments