Special Features

The owners of Black Forest pioneered running liquid and viscous products on a continuous motion bagger utilizing squeeze roller technology. Through the years they have made many improvements to enhance the performance of the machine. Two (2) of the most important are the squeeze roller station and horizontal seal jaws.

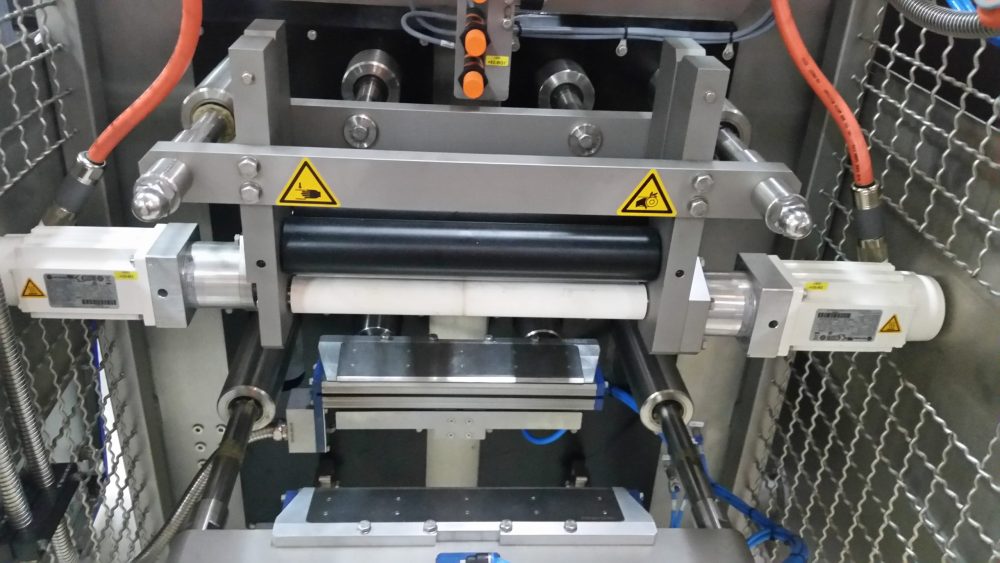

PowerClean Xtreme® Squeeze Roller Station

- Servo-driven (in/out motion)

- Servo-driven (rotation)

- Independently driven (rotation)

- Cleans the sealing area to eliminate product contamination

- Provides maximum seal integrity to help eliminate leakers

- Removes air from the bag for zero head space in most applications

- Direct drive – no chains, belts, or angled gear boxes that are found on most liquid baggers

- Fewer wear parts, less maintenance

- More consistent squeeze pressure control

- Minimizes film loss

- Maximizes machine uptime

Horizontal Seal Station

- Servo-driven (in/out)

- Servo-driven (up/down)

- Automatic jaw jam detection

- Servo-drive/motor provides maximum and precise seal pressure

- Optimizing the box motion travel profile of the jaws provides maximum dwell times throughout the sealing cycle resulting in bags with excellent seal integrity to help eliminate leakers

- Minimizes potential for jaw damage

- Minimizes film loss

LiquidSeal Xtreme® Horizontal Seal Jaws

- Chromium Copper execution

- Gold Titanium impregnated Teflon coating

- Specially engineered seal serration pattern

- Excellent heat transfer characteristics, far better than steel

- Superior coating durability

- Serration design helps eliminate product contamination, and provides maximum seal integrity to help eliminate leakers

- Minimizes film loss

- Maximizes machine uptime