LiquidMaster Standard Features

Every standard feature on the LiquidMaster serves to achieve the following goals:

- Maximize product throughput

- Maximize machine uptime

- Minimize maintenance

- Minimize film loss

Each of the features stands on its own as a benefit, but when combined with other critical features, the above is realized year after year of continuous production.

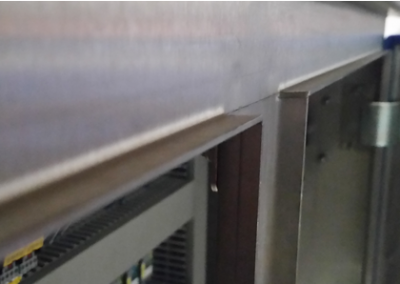

Machine Housing

Features

- IP65 heavy-duty, non-tubular, fully welded stainless steel machine frame and housing

- Cleaned and polished continuous welds

- No open holes or exposed threads

- Stainless steel fasteners throughout machine

- Stainless steel machine feet, no exposed threads

- Pressurized machine housing

Benefits

- Sanitary design prohibits bacterial growth

- Withstands aggressive sanitation procedures

- Pressurization helps prevent water ingress

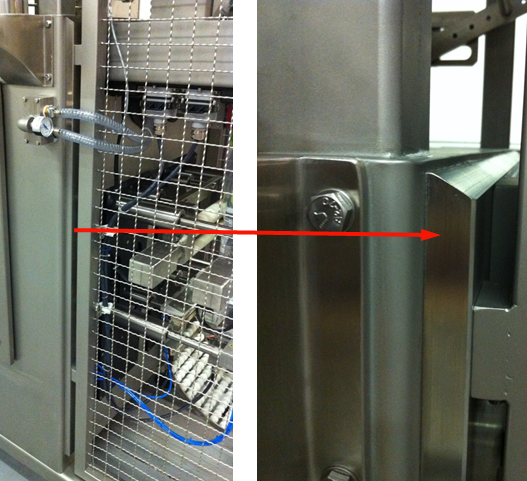

Front Plate

Features

- One-piece 20mm thick stainless steel front plate

Benefits

- Extremely strong and stable platform for mounting the forming set, vertical seal station, film draw down belts, squeeze rollers, and horizontal seal jaws

- Eliminates flexing of the front plate due to the combined weight and inertia of the above components

- Increased bearing life

- Increased shaft life

- Minimizes preventative maintenance

- Maximizes machine uptime

Electrical Cabinet

Features

- IP66 washdown execution

- Pressurized

- Offset from machine housing

- Cabling runs through offset mounts

- Sloped top

- Top overhangs doors

- Channeled door openings

- Heavy-duty chemical resistant gaskets

Benefits

- Withstands aggressive sanitation procedures

- Pressurization helps prevent water ingress

- Offset mount prohibits bacterial growth between electrical cabinet and machine housing

- Superior design with overhanging sloped top, channeled door openings, and heavy-duty chemical resistant gaskets

Overhead Product Catch Tray

Features

- Stainless steel construction, sloped, with drain

Benefits

- Protects machine, film, and printer during operation and clean-up

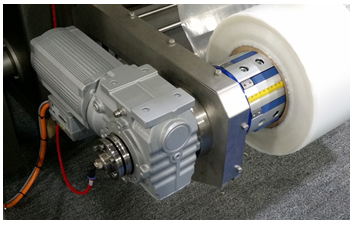

Powered Film Roll Unwind

Features

- Laser-controlled

- Laser reads exact position of dancer bar and sends signal to ACVFD

- ACVFD accelerates or decelerates film spindle rotation

Benefits

- Positive control of the film spindle keeps precise tension on the film

- Reduces film stress and slippage

- Reduces out of specification bags

- Minimizes film loss

- Maximizes machine uptime

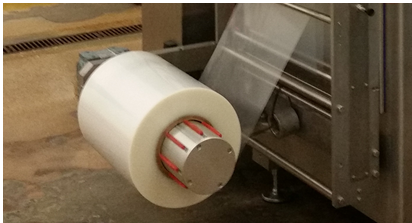

Film Spindle

Features

- 6” film spindle

- Cantilever design (280 machine)

- Low loading position of film roll

- Numerical scale for film roll positioning

- Film roll positioning locking collar

- Tool-less changeover

Benefits

- Fast, easy, and consistent film roll changes

- Ergonomic loading position of film roll

- Minimizes film loss

- Maximizes machine uptime

Low Film Detection

Features

- IP66 sensor

- Detects when film roll is running low, a message is displayed on the HMI, and the yellow light on tower stack light is actuated

Benefits

- Alerts operator to low film supply condition

- Maximizes machine uptime

Manual Splice Table

Features

- Stainless steel execution

- If the film roll runs out, the tension on the dancer bar released, and the machine stops automatically

- The pneumatic clamping cylinders automatically fire the top clamping bar to hold the old film in place on the splice table so it does not run out through the machine

- Tape head and positioning arm for manually splicing the two film rolls

Benefits

- Fast and easy film roll changes

- Minimizes film loss

- Maximizes machine uptime

Printer Frame

Features

- Stainless steel execution

- Tooless handwheel position adjustments with numerical readouts

Benefits

- No anodized aluminum

- Fast, easy, and consistent tooless changeovers

- Minimizes film loss

- Maximizes machine uptime

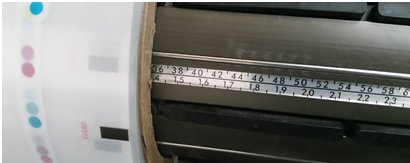

Print Registration

Features

- IP66 photoeye

- Capable of running printed/registered film

- Tooless handwheel position adjustment with numerical readout

Benefits

- Fast, easy, and consistent tooless changeovers

- Minimizes film loss

- Maximizes machine uptime

Automatic Film Tracking

Features

- IP66 infrared sensor

- The entire film feed carriage from the film roll to the forming collar moves

- Instantaneous film tracking adjustments

- Tooless position adjustment for changeovers

- Drive motor mounted inside the machine housing

Benefits

- Minimizes out of spec bags by maintaining the integrity of the vertical seal to help eliminate leakers

- Fast, easy, and consistent tooless changeovers

- Minimizes film loss

- Maximizes machine uptime

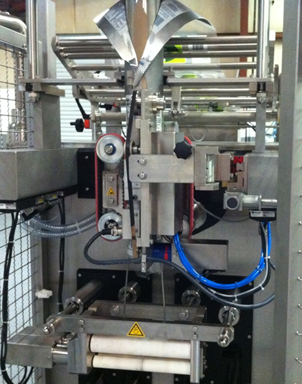

Forming Set

Features

- Stainless steel execution

- 27° collar angle coming off last roller

- Tooless changeover

Benefits

- Gentle angle reduces film stress

- Gentle angle reduces film slippage

- Gentle angle increases collar life while running heavier gauge films typically found in liquid operations

- Minimizes out of spec bags by maintaining the integrity of the eye mark position when running printed film

- Fast and easy changeovers

- Less film waste

- Maximizes machine uptime

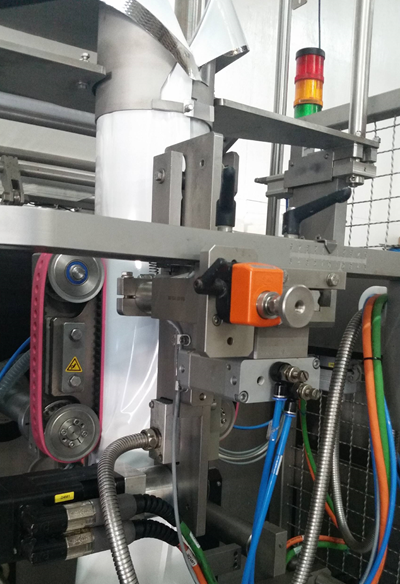

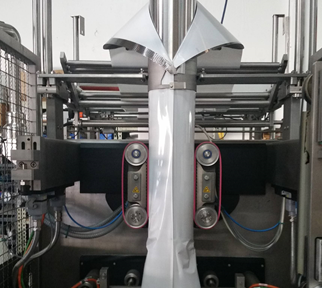

Film Drive Belts

Features

- Servo-driven vacuum-assist film drive belts

- Each belt is independently driven

- Piab vacuum pump

- Large contact surface area to film

- Automatic alignment with forming tube flats

- Tooless belt replacement

Benefits

- Precise film draw down

- Vacuum-assist is especially useful in wet environments, avoids film slippage

- Positive control of heavier gauge films typically found in liquid operations

- Minimizes film loss

- Maximizes machine uptime

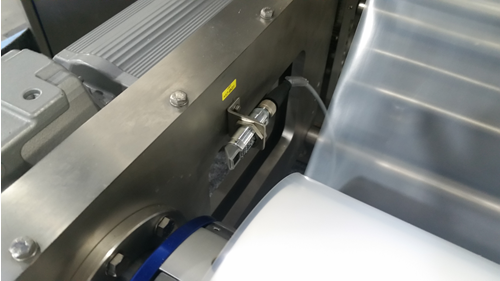

Vertical Seal Station

Features

- Servo-driven, direct drive

- Synchronized with the film drive belts

- Open access design with tooless release mechanism

- Tooless adjustment

- Tooless band replacement

Benefits

- Quick and easy access for changeovers, maintenance, and cleaning

- Quick and easy band replacement

- Quick, easy, and consistent adjustment during changeovers

- Minimizes film loss

- Maximizes machine uptime

Tower Stack Light

Features

- Alerts operator and surrounding personnel to machine operating status and conditions

Benefits

- Safer machine operation

- Alerts can prepare operator for upcoming conditions (i.e. low film roll supply)

- Maximizes machine uptime

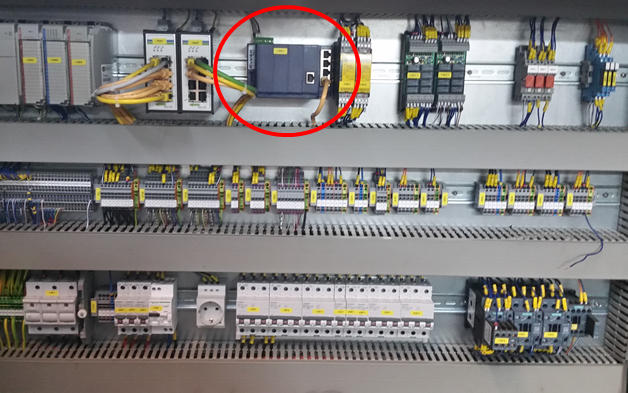

eWon Module

Features

- Provides remote diagnostic capabilities

Benefits

- Helps eliminate the need for a service technician visit

- Minimizes machine downtime